What is Remote Maintenance and Why Should I Care?

Remote Maintenance

Remote Maintenance with MB Connect

Have you ever wondered how "remote maintenance" really works or how it can benefit you? To many, it is difficult to comprehend, but the technology has come a long way and it's actually quite simple. There are a few dominant players in this space, and TSI is proud to represent MB Connect solutions for highly secure remote maintenance.

In a nutshell, remote maintenance is the ability for a controls engineer or technician to login to an industrial control system remotely and securely over the internet to perform diagnostics and maintenance on a machine located somewhere else in the world. That's it! Pretty simple. This is an enormous benefit to both the user of the equipment and the machine builder, as it provides both the possibility for immediate troubleshooting and potential for addressing an issue in real time. Remote maintenance, drastically reduces costly downtime and increases production while eliminating unnecessary travel and expense on the behalf of the original equipment manufacturer.

What's not to like?

Well, for starters, it seems that some (not all) IT groups in manufacturing facilities still don't fully understand the core technology and worry that it will open their network to vulnerabilities and unnecessary risks. This is certainly understandable but needs to be addressed. This article is not going into the full technical details, specifications and certifications that these products meet for network security, but if you have interest in speaking at that level of detail, we can arrange for such a conversation. For now, let's just say that these products provide a highly secure remote VPN tunnel into the machines in which they are installed. They do not allow a user to access anything else on the plant or office network other than the products which are plugged directly into them, which may include PLC's, Drives, HMI's, Sensor Networks, etc. If an IT group still won't allow a machine to access to the internet, or if the equipment itself is not tied to a network, these remote maintenance products can be ordered with cell modems, which can access the internet using a mobile connection.

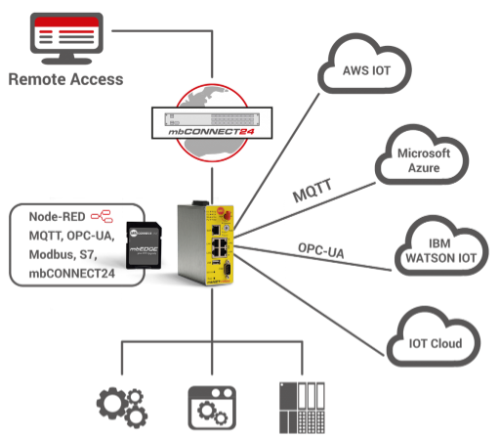

In addition to providing access for remote maintenance, many of these products can also provide data acquisition, which can be used by both the end user and the machine builder to inform personnel of a potential issue in advance of a problem or to notify them to order replacement parts that are due for scheduled maintenance. These technologies are all part of the digital transformation, IIoT, M2M or Industry 4.0. Whatever you want to call it. This is real and it's going to make adopters more efficient and more competitive in their markets.

Call us to speak with a specialist if you'd like to learn more or to discuss an application at (844) 910-2091

SECURITY IS AN ATTITUDE

SECURITY IS AN ATTITUDEWhat are the security risks in industrial communication? We ask ourselves this question at all stages of development. Safe systems and devices require a safe development process. The development engineers of MB connect line are certified accordingly.

For this purpose, we rely on a TÜV expert certification program in the field of secure software development and on expert knowledge in the field of IT security (Teletrust T.P.S.S.E.).