Old to new - upgrading valve manifolds

A modernization success story at an Atlanta Beverage Manufacturer

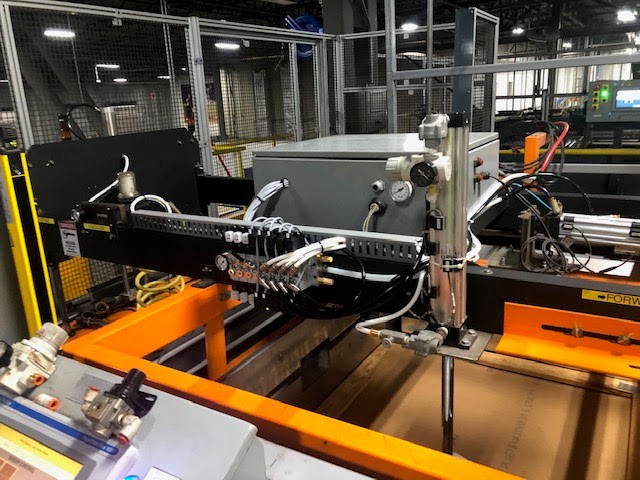

An Atlanta-based beverage manufacturer has a fleet of depalletizers, each with end-of-arm-tooling to pick and place corrugated slip sheets. Each EOAT had an obsolete valve manifold (pictured) with leaking seals and sticking spools.

The repeated valve failure created an unrepeatable pick cycle for the slip sheets, resulting in unplanned down time, repeated maintenance requests, and ultimately a loss of production.

This is a great example of a common issue many plants face: old and failing pneumatic components that need modernizing, coupled with the lack of manpower and time required to diagnose, design, replace, and commission.

TSI Solutions' team of Automation Specialists and Applications Engineers excel at identifying and fixing these exact problems. One of our Certified Fluid Power Pneumatic Specialists (CFPPS) was able to assess the machine, diagnose the problem, and propose a solution, in this case a new Festo VUVG Valve manifold.

The installation of the new manifold took half a day, and included removing the old valve manifold, mounting the new Festo manifold, rewiring the solenoids, and replumbing the airlines.

Close up of the new Festo VUVG valve manifold.

The new manifold mounted on the machine.

Do you have old, outdated equipment that needs replacing?

TSI Solutions is a great resource to help in your plants' efforts to modernize. Our team is equipped to help you start to finish, from identifying and diagnosing faulty and failing pneumatic equipment, suggesting and supplying modern solutions, to installing the new equipment on site and providing post-install support. Contact Us today to learn more!