Banner In-Series Diagnostics for Safety Systems

Easy-to-Implement Diagnostic Capabilities

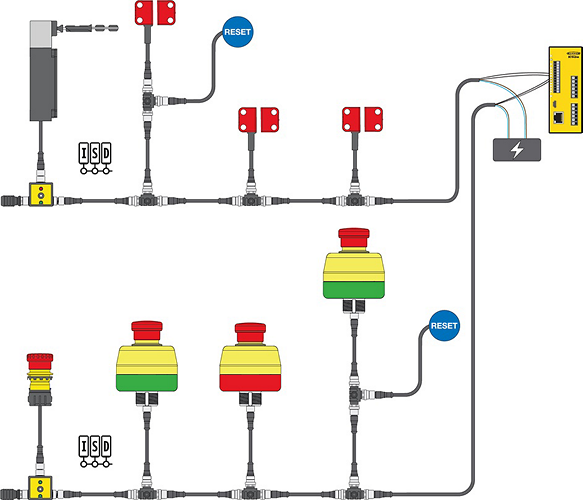

In-Series Diagnostics (ISD) makes it easy to access diagnostic data from devices in a safety system without special equipment or designated cabling. Users can troubleshoot machine safety systems, prevent system faults, and reduce equipment downtime. This innovative, next-generation technology is exclusive to safety devices from Banner Engineering.

In-Series Diagnostics gives machine owners and operators greater insight into the health and performance of their equipment, making them less reliant on outside experts to solve system problems. Users can monitor the status of each device in their safety system in real-time, identify the location and nature of any potential problems, and receive alerts if a critical event does occur, so equipment can get back up and running as soon as possible.

The technology that makes In-Series Diagnostics possible is embedded in the safety devices and communicated using the same cables, connectors, adapters, and inputs that connect the devices to the safety controller. This eliminates the time, hassle, and expense of running designated cabling between each device and the control panel in order to access diagnostic data. Users can add, move, or remove safety devices as needed and then easily error-proof the entire safety system prior to deployment.

Data is collected from up to 8 ISD chains and up to 32 devices in each

In-Series Diagnostic chain. Using an HMI or similar device, users can

view the status and location of each device and drill into the data to

determine the unique tag value, internal temperature, voltage, and other

device-level details. System alerts notify staff if a monitored door

has been opened, an E-Stop button pressed, or any other critical event

has occurred.

Contact us today to learn more about Banner's ISD technology, or browse our catalog of Banner safety products and more.

Tags

banner engineering

TSI Solutions

festo

Bimba

pneumatic

Banner Engineering

Pneumatic

Actuators

actuators

valves

iiot

sensors

Wago

Training

grippers

destaco

safety

ace controls

shock absorbers

wago

turck

lighting

puls

power supply

industry 40

Terminal Blocks

Piab

Vacuum

IIoT

T-Slots

TRD

Kollmorgen

Motors

Lighting

Turck

IP67

Posts

2022

August

2021

Pneumatic Gripper Basics - What Are They, How to Use

[08/31/22 11:57 AM]

Plant Modernization - Valve Upgrade Success Story

[08/02/22 10:04 AM]

May

March

February

September

2020

ACE Shock Absorbers Motion Control Vibration Damping

[09/28/21 01:46 PM]

Wago's new Edge Controller Computer

[09/28/21 12:57 PM]

July

Turck Introduces New FS Flow and Temp Sensor

[07/14/21 03:20 PM]

Banner Engineering Pro Editor LED Lighting Solutions

[07/14/21 02:11 PM]

June

May

November

2018

2017

Photoelectric Sensors - Everything You Need to Know

[11/26/20 01:16 PM]

Selecting the Right Pneumatic Flow Control Valve

[11/26/20 12:43 PM]

October

October

September

Wago PCB Terminal Blocks

[09/27/17 09:13 AM]

Are You Ready For The Revolution? PackExpo 2017

[09/21/17 12:09 PM]

New CODESYS-programmable RFID interface Module from Turck

[09/08/17 02:51 PM]

Piab Duraflex Range Expanded to Include Smaller Suction Cups

[09/01/17 09:25 AM]

August

Banner Smart Factory

[08/21/17 02:05 PM]

Buy Tslot Extrusions

[08/18/17 02:32 PM]

Bimba TRD Alignment Coupler

[08/16/17 11:52 AM]

Kollmorgen Stepper & Servo motors recognized for Excellence

[08/14/17 10:15 AM]

Are You Ready for Predictive Maintenance

[08/09/17 10:12 AM]

Turck Compact IP67 Controller with CODESYS 3

[08/07/17 12:48 PM]

Bimba's Product Spotlight

[08/01/17 10:41 AM]

July

June

The Lowdown with Larco

[06/20/17 01:09 PM]

June E-Newsletter

[06/15/17 11:30 AM]

Saftey is Everyone's Business

[06/12/17 02:41 PM]

New Bimba Products Update

[06/05/17 08:43 AM]

May

January